Distributed gap wound core forming machine

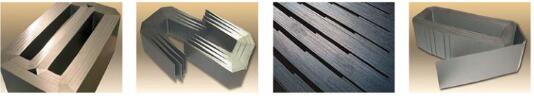

Full automatic Unicore machine distributed gap core forming machines also called 3D unicore machine for cutting transformer core cut a variety of small medium and large transformer core in open U type,Triangle type,new developed with autmatic material receiving device.

Detailed introduction

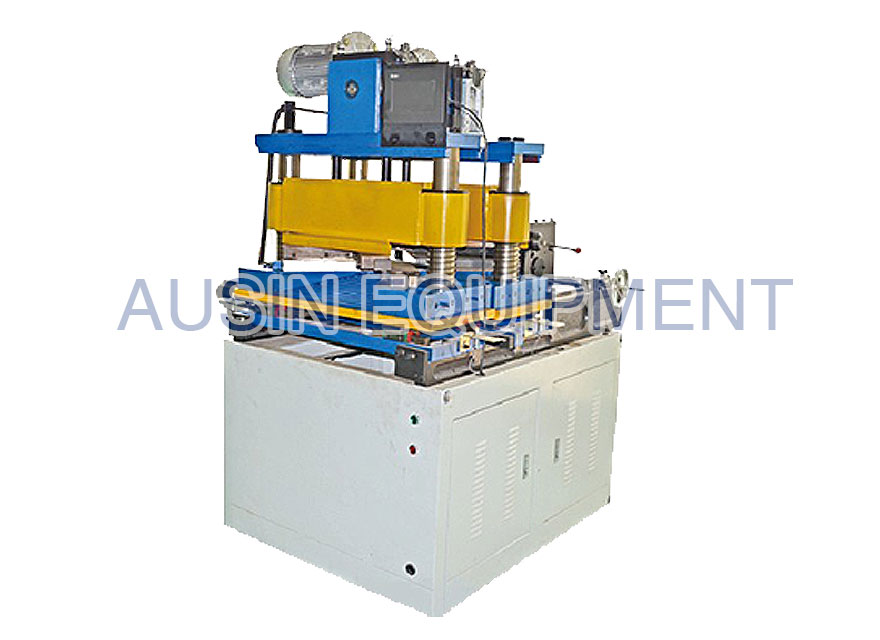

Full automatic distributed gap core forming machine

Unicore machine

Type 1

1. This machine can produce a variety of small medium and large transformer core

2. This machine can produce single-phase, three-phase, three-dimensional transformer core

3. This machine can produce dry, oil-immersed transformer core. Equipment processing core can be used to manufacture oil-immersed, dry, traction, rectifier, grounding transformers and special transformers, reactors, transformers and other products.

4. This machine cut the cores in high dimensional accuracy, and with simple operation and convenient

5. This machine can be processed at the same time with two silicon steel strip

6. Bending, cutting with full servo CNC system

7. The machine interface is applied by human-computer interaction, PLC control

8. Equipment can process the curve; the line can be produced with R-shaped silicon steel, oval, three-dimensional triangular transformer open core

Type 2

This machine is developed by ourselves, designed for cutting distributed gap cores in single phase or three phase distribution transformers and instrument transformers 500kVA ~ 5000kVA.

It has flexible software similar to Unicore UCM machines, for different wound gap cores:

Main features of distributed gap core cutting machine

- Suitable for both single strip or double strips feeding

- PLC control, HMI operation

- Servo feeding, bending & cutting, high precision, high speed

- Compact structure, small occupation area

Uncoiler:

Open-book shrinkage range: 450mm-520mm

Open-book machine mandrel with hydraulic control

Maximum carrying capacity 1000 kg or 2000kg

Speed control with non-contact sensor

Input power: 380KV

JN-400: 1 processing a single group of silicon steel sheet, piece width 400MM,

2, the processing of dual-group silicon steel, 2 * width 190MM (optional)

10. The processed core is less burr, and no more than 0.02MM, length accuracy tolerance is less than or equal to 0.02mm, each length accuracy tolerance is less than or equal 0.10mm.

Process the silicon steel sheet thickness 0.15mm-0.35mm.Bending angle of 30 degrees, 45 degrees.

Online order

Could not find any data!

You may also be interested in these...

Center limb transformer core cutting machine

Center limb core cutting machine is especially designed for cutting center limbs of the power transformer core.

This machine is PLC control, touch screen operation. If the transformer core laminat...

Distributed gap wound core forming machine

Full automatic Unicore machine distributed gap core forming machines also called 3D unicore machine for cutting transformer core cut a variety of small medium and large transformer core in open U type...

CRGO Slitting machine

Slitting machine,the configuration of the sensor, length measuring device, intelligent digital display meter, the cutting length that required can be preset,(unit precision:0.1m) sound alarm when reac...